Home » Beer Production Line

Glass Bottle Beer Filling Line – Reliable & Turnkey Solution

Glass bottle beer… the variety of beer products and packaging formats is constantly evolving. New trends, new recipes, and innovative packaging are emerging continuously. For glass bottle beer filling lines, challenges are many: how to control filling temperature to reduce energy consumption, how to minimize foaming, how to ensure accurate filling, how to avoid residue in the bottle neck, and how to preserve carbonation. Handling all these factors is not an easy task.

However, no matter the beer type, Newpeak Machine delivers the best technology to achieve your production goals. With efficient cost control, we help our customers strike the perfect balance between diversified production capabilities and high-quality packaging. At the same time, market competitiveness is enhanced thanks to the efficient operation mode of our equipment.

Blending system

The machine injects carbon dioxide using a venturi system to maintain a constant flow and precise, adjustable mixing ratio. It supports high-speed production without part changes and allows easy control of the wine-to-water ratio.

With an automatic control system, it ensures coordinated operation, simple structure, and high automation. The integrated CIP cleaning design provides easy maintenance, hygienic operation, and full compliance with food safety standards.

beer Filling Machine

The beer isobaric filling machine is specially designed for carbonated beverages such as beer, sparkling wine, and soda. It adopts equal-pressure filling technology to maintain carbonation, reduce foaming, and ensure stable taste and quality.

This equipment integrates rinsing, filling, and capping into one system, suitable for glass bottles, PET bottles, and cans. With features of high efficiency, easy operation, and reliable performance, it is an ideal choice for modern breweries seeking automation and consistent product quality.

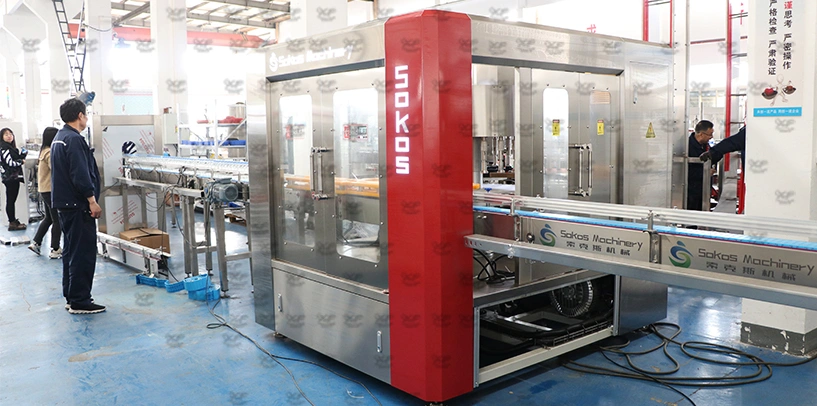

Labeling Machine

The hot melt glue labeling machine is designed for high-speed and precise labeling of PET bottles, glass bottles, and cans. It adopts advanced hot melt adhesive technology to ensure strong adhesion, smooth application, and a neat appearance even under high production speeds.

With features such as low glue consumption, stable operation, and easy adjustment, it helps reduce production costs while improving efficiency. Widely used in the beverage, food, and daily chemical industries, this machine is an ideal labeling solution for modern automated production lines.

| Model | BGF6-6-1 | BGF14-12-5 | BGF18-18-6 | BGF50-50-15 |

| Capacity (BPH) | 2000 | 3000 | 5000 | 20000 |

| Motor power(KW) | 2.5 | 3 | 4 | 5.5 |

| Dimensions | 1800*1500*2500 | 2100*1500*2500 | 2600*2200*2500 | 3000*2250*2500 |

| Weight(KG) | 2500 | 3300 | 4800 | 5800 |

Beer Filling Machine Specifications

- Fully automated PLC control with touch screen interface

- Advanced CO₂ mixing technology for uniform carbonation

- Unique sealing technology and wire capping machine for champagne and high-pressure beverage lines

- Equipped with international electrical brands like Siemens and Schneider for stable operation

Leave a Message

Don’t hesitate—successful cooperation starts with a simple conversation.