Home » Beer Filling Machine

Automatic Beer Filling Machine

NewPeak Machinery complete glass bottle beer production lines are suitable for all types of beer, including raw beer, dry beer, whole malt beer, wheat beer, black beer, and fruit-flavored beer. Our lines have been installed in 200+ countries and regions across Asia, America, Europe, and Africa. With 15 years of industry leadership, we offer patented technology, long-lasting equipment, rich experience, and excellent service.

A fully connected line helps optimize performance and enables smarter decisions throughout its lifetime. Our holistic approach provides flexibility, efficiency, minimal waste, quick SKU changeovers, and reduced environmental impact. Careful packaging design, detailed equipment planning, and a flexible line setup ensure reduced resource consumption, consistent bottle durability, and high efficiency.

Container Compatibility

Glass Beer Bottles

Designed for glass bottles of different shapes and sizes. Supports cold and hot filling, maintaining beer freshness and carbonation. Ideal for craft beer, lager, wheat beer, and specialty beers.

Aluminum Beer Cans

Compatible with aluminum cans of different sizes. Fast and accurate filling, sealing, and labeling for high-speed production lines. Reduces product loss and ensures consistent quality.

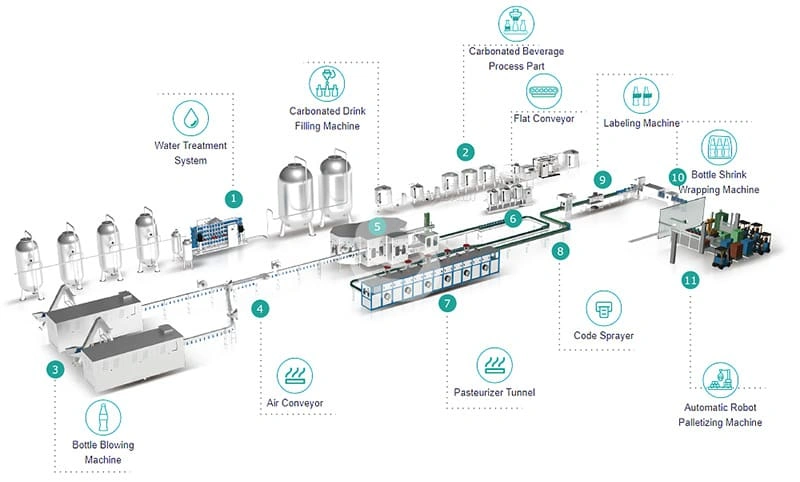

Beer Filling Machine Flow Chart

The beer isobaric filling machine delivers efficient, high-speed, and hygienic filling for carbonated beverages, including beer, sparkling wine, and soda. Its equal-pressure technology preserves carbonation and minimizes foaming, ensuring consistent taste and product quality.

| Complete full automatic 3-in-1 glass bottle beer filling machine 400-25000BPH | Carbonated water / Soft Drink / Beer | |||

| Bottle Material | Bottle Shape | Filling Volume | Filling Level (mm) | Cap Type |

| Glass Bottle | Round Bottle | 200-2000ml | Distance from bottle neck according request | Screw cap Crown cap |

| Adjustable specifications of the bottle type | (Middle Mould Base) Bottle diameter: Φ50~Φ85mm Bottle Height: 105~300mm | |||

| Customers need to buy additional change-over parts for the different bottles.If using square bottles, then bottle separating system will be added. | ||||

| Carbonated Drink Preparation | Syrup melter / Mixing machine / Filter / CO2 Filter / CO2 Mixer …../td> | |||

| Filling Precision | Syrup melter / Mixing machine / Filter / CO2 Filter / CO2 Mixer …../td> | |||

Beer Production Line Product Introduction

The beer production line is designed for efficient and hygienic brewing, filling, and packaging of beer. It integrates key processes such as water treatment, blending, filtration, filling, capping, labeling, and packaging into one automated system.

Blending System Description

The machine injects CO₂ using a venturi system for precise, adjustable mixing. Supporting high-speed production without part replacement, it allows easy adjustment of beverage ratios. With automatic controls and in-situ CIP cleaning, it ensures continuous, hygienic, and food-safe operation.

Blowing System Description

The fully automatic blow molding machine produces PET bottles with high efficiency and precision, integrating preform heating, blowing, and molding in one process. Features like fast changeover, energy-saving heating, and intelligent control reduce labor, boost productivity, and ensure consistent quality for beverages.

Beer Filling System

The beer isobaric filling machine is designed for carbonated drinks like beer, sparkling wine, and soda. Using equal-pressure technology, it preserves carbonation, reduces foaming, and ensures consistent quality. Integrating rinsing, filling, and capping, it supports glass, PET bottles, and cans with high efficiency and reliability.

Labeling Machine Description

The hot melt glue labeling machine provides high-speed, precise labeling for PET bottles, glass bottles, and cans. Advanced hot melt technology ensures strong adhesion and neat appearance. With low glue use, stable operation, and easy adjustment, it boosts efficiency and reduces costs for beverage, food, and chemical production lines.

Packaging System Description

The beer isobaric filling machine is designed for carbonated drinks like beer, sparkling wine, and soda, using equal-pressure technology to preserve carbonation and reduce foaming. After filling and labeling, bottles move via conveyors to secondary packaging, enhancing shelf appeal and protecting against weather, pressure, and temperature changes.

FAQ——Frequently Asked Questions

What types of containers does the beer filling machine support?

It is compatible with glass bottles, PET bottles, and aluminum cans of various shapes and sizes.

Can the machine handle carbonated beverages without foaming?

Yes, the isobaric filling technology preserves carbonation and minimizes foaming for beer, sparkling wine, and soda.

What is the production capacity of the beer filling machine?

Depending on the model, it can fill 2,000–30,000 bottles per hour for 500ml bottles, adjustable by filling heads and line speed.

How is the machine cleaned and maintained?

It comes with a CIP (Clean-in-Place) system for automatic internal cleaning of pipelines, valves, and tanks without disassembly.

What after-sales support is provided?

We offer a one-year warranty and lifetime technical support, including installation guidance, spare parts, remote troubleshooting, and operator training.