Home » Juice Filling Machine

Automatic Juice Filling machine

Hot filling technology for fruit juice, tea and functional drinks.The juice filling machine is designed for filling fruit juice, tea drinks, and functional beverages. It integrates washing, filling, and capping in one compact unit, suitable for hot filling and PET bottles. The system ensures precise temperature control, hygienic operation, and stable performance.

Juice Filling Machine Components

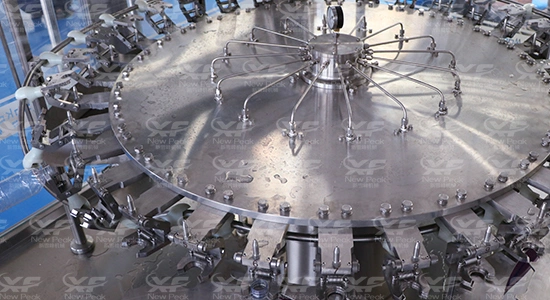

Rinsing Part

The washing heads are key components of the bottle cleaning system in filling lines. They spray high-pressure water or cleaning solution inside the bottles to remove dust, debris, and contaminants before filling. Made from food-grade stainless steel, they ensure hygienic operation and durability. The number and arrangement of washing heads can be customized according to bottle size and production speed, ensuring thorough cleaning for each container.

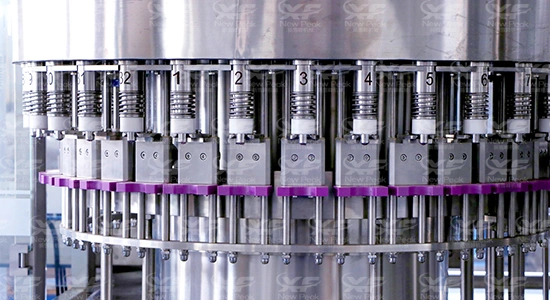

Filling Part

Filling heads are the key components of a liquid filling machine, responsible for accurately dispensing beverages or other liquids into bottles or containers. Designed for precision, speed, and hygiene, they minimize spillage and ensure consistent volume in every container. Made from food-grade stainless steel and equipped with advanced valves, the filling heads can handle a wide range of liquids, from water and juice to viscous sauces.

Capping Part

Capping heads are essential components of a filling line, responsible for securely sealing bottles or containers after filling. Designed for precision and stability, they ensure consistent torque and proper alignment, preventing leaks and maintaining product quality. Made from durable, food-grade materials, capping heads can handle various cap types, including screw caps, crown caps, and flip-top lids, and can be customized for different bottle sizes.

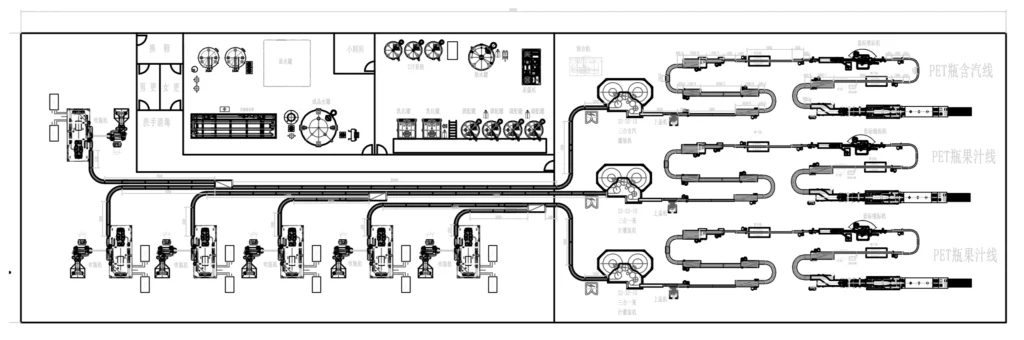

Total Solution Floor Plan

The complete automatic juice beverage production line is mainly composed of water treatment units, fruit juice blending and sterilization systems, a 3-in-1 hot filling machine, pasteurizer, blow-drying equipment, labeling machine, packaging equipment, and a CIP cleaning system.

Product Parameters:

Technical parameter : Juice Filling Machine | ||||||

Model | RCGF14-12-5 | RCGF16-16-5 | RCGF24-24-8 | RCGF32-32-8 | RCGF40-40-12 | RGF60-60-15 |

Capacity(for 500ml) | 2000BPH | 4000BPH | 8000-10000BPH | 12000-15000BPH | 16000-18000BPH | 24000BPH |

Suitable bottle shapes | circular or square | |||||

Bottle diameter(mm) | Dia50-Dia115mm | |||||

Bottle height (mm) | 160-320mm | |||||

Filling type | Overflow filinig type /Hot filling | |||||

Function | Rinsing filling capping | |||||

Rinsing pressure | >0.06Mpa <0.2Mpa | |||||

Application | Juice / Tea drinks / Milk Beverage | |||||

Total power (KW) | 4.4kw | 4.4kw | 4.4kw | 5.2kw | 6.2kw | 7.8kw |

Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

Weight(kg) | 3500kg | 5200kg | 7000kg | 9500kg | 10500kg | 12000kg |

Technical Highlights

1.High degree of automation

The system automates the entire process, from can sorting, rinsing, filling, and sealing to conveying, which greatly reduces manual labor and enhances production efficiency.

2.Precise filling and good foam control

Adopting isobaric or hot filling technology, precise filling, low loss and good foam control, especially suitable for carbonated or aerated beverages.

3. Intelligent Control Can Juice Filling Machine

adopt Rinsing/ Filling/Capping 3-in-1 technology, PLC control, Touch Screen, it is mainly made of SUS304/SUS316.

4.Reliable and strong sealing

Equipped with a high-speed rotary sealing machine, it ensures that the sealing of each can opening is tight and flat, preventing leakage and contamination, and enhancing the shelf life of the product.

5. Wide range of application

Suitable for can filling of juice, tea drinks, carbonated drinks, beer, energy drinks and many other liquids, supporting aluminum cans and tin cans of different capacities and specifications.

6.Customizable

Customers can flexibly configure the number of filling heads, production line layout, and other functional modules based on their requirements for production capacity, beverage types, and can specifications.

FAQ——Frequently Asked Questions

To help our customers better understand our Automatic Juice Filling Machine and the complete juice beverage production line, we have summarized the most common questions regarding bottle compatibility, production capacity, hot filling, cleaning, customization, and after-sales service.

What types of bottles can the juice filling machine handle?

Our juice filling machine suits PET, glass, and aluminum bottles of various shapes and sizes. By adjusting clamps and filling valves, it ensures precise filling for bottles from 200ml to 2L, ideal for juice, tea drinks, and functional beverages.

What is the production capacity of the automatic juice filling line?

Depending on the model, our juice filling machine offers 2,000–30,000 bottles/hour for 500ml bottles. Capacity can be customized by adjusting filling heads or line speed. Optimized for stability, it maintains high accuracy and efficiency for large-scale juice production.

Can the machine perform hot filling for juice products?

The machine supports hot filling at 85–95°C, effectively killing microorganisms and extending juice shelf life. Ideal for juices, tea, and preservative-free drinks, it features food-grade stainless steel valves and pipelines for safe and hygienic high-temperature filling.

Is it easy to clean the juice filling machine?

Equipped with a CIP system, the machine cleans and sterilizes pipelines, valves, and tanks automatically without disassembly. Operators simply start the preset program, ensuring hygiene, saving labor, and improving efficiency. Cleaning intensity adjusts by juice type to ensure food safety.

Can the machine be customized according to my production needs?

We provide customized juice filling solutions based on bottle size, capacity, and juice type. Customers can choose filling heads, hot or cold filling, and material transfer methods. Our engineers design efficient, safe, and cost-effective lines tailored to each factory layout.

What is the warranty and after-sales service?

We offer a one-year warranty and lifetime technical support, including online guidance, spare parts, and remote troubleshooting. From installation to maintenance, our team ensures stable line operation. Global after-sales service responds quickly to minimize downtime and maintain efficiency.