Carbonated Beverage Filling Machine

Automatic Soda & Soft Drink Bottling Line for PET and Glass Bottles

Home » Carbonated Beverage Filling Machine

Our Carbonated Beverage Filling Machine is specially designed for bottling soda, sparkling water, energy drinks, flavored carbonated beverages, and other fizzy drinks. The machine supports PET bottles, glass bottles, and aluminum cans, providing a flexible solution for different packaging types and production requirements.

Carbonated Beverage Filling Machine

Our Carbonated Beverage Filling Machine is specially designed for bottling soda, sparkling water, energy drinks, flavored carbonated beverages, and other fizzy drinks. The machine supports PET bottles, glass bottles, and aluminum cans, providing a flexible solution for different packaging types and production requirements.

Carbonated Beverage Filling Machine Components

Bottle Rinsing System

The washing heads are key components of the bottle cleaning system in filling lines. They spray high-pressure water or cleaning solution inside the bottles to remove dust, debris, and contaminants before filling. Made from food-grade stainless steel, they ensure hygienic operation and durability. The number and arrangement of washing heads can be customized according to bottle size and production speed, ensuring thorough cleaning for each container.

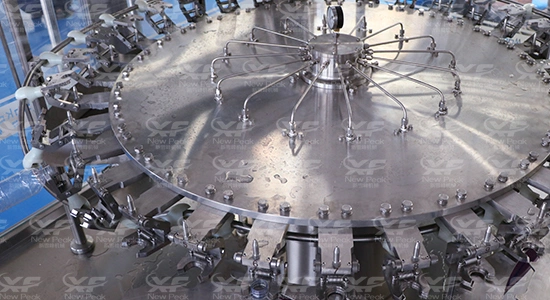

Isobaric Filling System

Filling heads are the key components of a liquid filling machine, responsible for accurately dispensing beverages or other liquids into bottles or containers. Designed for precision, speed, and hygiene, they minimize spillage and ensure consistent volume in every container. Made from food-grade stainless steel and equipped with advanced valves, the filling heads can handle a wide range of liquids, from water and juice to viscous sauces.

Capping System

After filling, bottles or cans are sealed immediately using an automatic capping or can-seaming system. This section ensures perfect sealing to prevent CO₂ leakage and contamination, extending the beverage’s shelf life.

Total Solution Floor Plan

The complete automatic carbonated beverage production line mainly consists of water treatment units, beverage mixing and carbonation systems, an isobaric filling machine, pasteurizer, blow-drying equipment, labeling machine, packaging system, and a CIP cleaning unit. Each component works seamlessly together to ensure stable carbonation, accurate filling, and hygienic packaging for soft drinks, soda water, energy drinks, and other sparkling beverages.

Product Parameters:

| Carbonated Beverage Filling Machine | |||

| Adjustable specifications of the bottle type | |||

| Material | Shape | Can diameter | Adapt can height |

| Aluminum can / PET can | Round | Φ52.3~Φ65.5mm | 39~160mm |

| Total power | Power voltage | Control voltage | Air consumption |

| 11KW | 380 V 50HZ 3phase+N+G | 24 V DC/AC | 1m³/h |

| Packaging system | Palletizing system | ||

| Packing system | Min, Spec. | Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer | |

| Half-tray Carton Box | 2×3 3×4 4×6 3×5 | ||

Key Features

High Automation

Equipped with advanced PLC and touch screen control, the system integrates bottle conveying, isobaric filling, and capping/sealing into a fully automatic operation, ensuring high efficiency and stability.

Accurate Carbonation Control

The carbonation and pressure regulation system ensures consistent CO₂ levels in every bottle, maintaining the perfect fizz and preventing overflow or foam loss.

Multiple Packaging Compatibility

The filling system is adaptable for PET bottles, glass bottles, and aluminum cans, allowing manufacturers to serve various markets and product lines with one production line.

CIP Cleaning System

The built-in CIP (Clean-in-Place) system enables internal pipeline and valve cleaning without manual disassembly, ensuring hygiene and product safety.

Flexible Production Capacity

The system can be configured with different numbers of filling heads, supporting capacities from 2,000 to 30,000 bottles per hour according to customer requirements.

FAQ——Frequently Asked Questions

What types of bottles or cans can this machine fill?

Our carbonated beverage filling machine is compatible with PET bottles, glass bottles, and aluminum cans. The machine adopts modular design, so only minor adjustments or change parts are needed to switch between different container types.

How does the machine control carbonation levels?

The system uses an isobaric filling technology with precise CO₂ pressure control. This ensures each bottle retains stable carbonation, preventing excessive foaming or CO₂ loss during filling.

What is the production capacity of the carbonated filling line?

Depending on the model and number of filling valves, production capacity ranges from 2,000 to 30,000 bottles per hour. We can customize the configuration according to your production volume and packaging type.

Is the machine suitable for carbonated drinks with pulp or high viscosity?

Generally, standard carbonated filling machines are designed for clear liquids. For drinks with pulp or higher viscosity, we provide customized isobaric-pulp filling systems that prevent clogging and maintain product integrity.

How is hygiene maintained during production?

The line is equipped with a CIP (Clean-in-Place) system that automatically cleans internal pipelines, filling valves, and tanks without disassembly. All materials in contact with beverages are made of food-grade stainless steel (SUS304/316).

Can you provide a turnkey solution for the entire production line?

Yes. We offer complete turnkey solutions including water treatment, carbonating mixer, isobaric filling machine, labeling, packaging, and CIP systems. Our engineers provide installation, commissioning, and operator training services worldwide.