Home » Water Filling Machine

High-Speed Liquid Filling Machines

Our pure water production line is designed to provide a complete solution for producing high-quality purified drinking water. The system includes advanced water treatment, precise bottle blowing, high-speed rinsing, filling, and capping, followed by labeling and packaging. It ensures safe, hygienic, and efficient production with a capacity customizable to meet different factory needs. This production line is widely used for bottled pure water in PET bottles of various sizes, offering stable performance and long service life.

Bottled Water Filling Machine

NewPeak bottled water filling machines are designed for producing pure water and mineral water in PET bottles ranging from 200ml to 2L. The line integrates bottle rinsing, filling, and capping into one compact system, featuring high automation and hygiene standards.

Production capacity ranges from 2,000 to 24,000 bottles per hour, depending on bottle size and configuration.

It is widely used in small and medium beverage plants, mineral water factories, and turnkey bottling projects.

Large bottle of mineral water

NewPeak bottled water filling machines are designed for producing pure water and mineral water in PET bottles ranging from 200ml to 2L. The line integrates bottle rinsing, filling, and capping into one compact system, featuring high automation and hygiene standards.

Production capacity ranges from 2,000 to 24,000 bottles per hour, depending on bottle size and configuration.

It is widely used in small and medium beverage plants, mineral water factories, and turnkey bottling projects.

5 Gallon Water Filling Machine

The 5-gallon water filling machine is specially designed for 18.9L (5-gallon) barrels used in purified and mineral water plants.

The system includes automatic barrel decapping, washing (with alkali and pure water), filling, and capping processes, ensuring strict hygiene control.

Production capacity ranges from 100 to 1,200 barrels per hour, ideal for medium and large-scale bottled water factories.

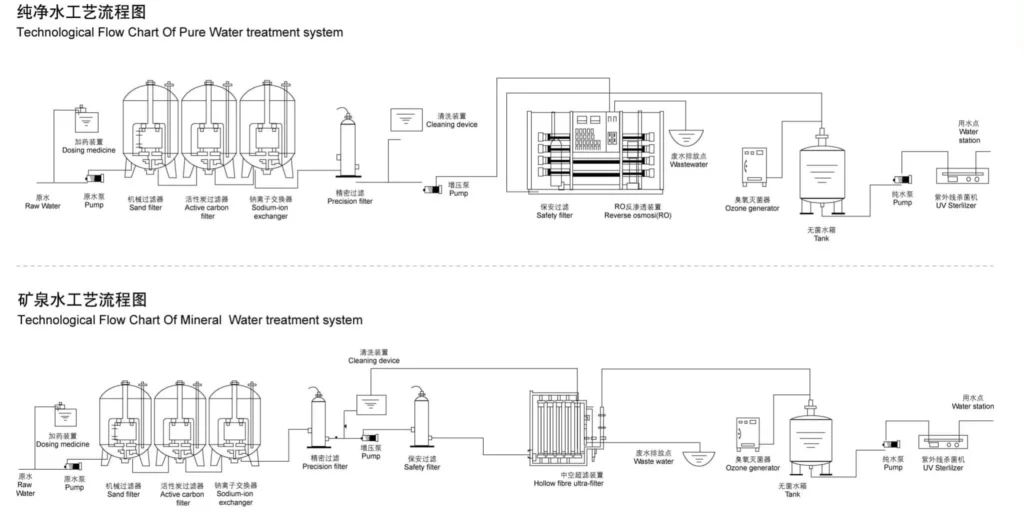

Production Process

| Model | CGF8-8-4 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 |

| Capacity (BPH) | 1000-2000 | 3000-5000 | 6000-8000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 |

| Power supply | 2.2kw | 2.42 KW | 3.12 KW | 3.92 KW | 3.92 KW | 5.87 KW | 7.87 KW |

| Overall dimension | 1830x160x2050 | 2360×1770×2700 | 2760×2060×2700 | 2800×2230×2700 | 3550×2650×2700 | 4700×3320×2700 | 5900×4150×2700 |

| Weight (KG) | 2100 | 2500 | 3500 | 4200 | 5500 | 6800 | 7600 |

Production Line Flow

High efficiency, strict quality control, and one-stop service — helping you reduce costs and boost productivity with reliable filling solutions.

Water Treatment System — Ensure Pure, Safe, and Reliable Water for Every Production Line

Product Introduction

NewPeak water treatment systems are designed to deliver safe, pure, and high-quality water for beverage, bottled water, and liquid food production lines.

Using advanced purification technology and durable design, our equipment ensures stable performance, long service life, and full compliance with international hygiene standards.

Working Principle

1️⃣ Pre-Filtration – Removes large particles, sediments, and suspended solids to protect downstream equipment.

2️⃣ Activated Carbon Filtration – Eliminates chlorine, organic matter, odor, and harmful chemicals to improve taste and safety.

3️⃣ Reverse Osmosis (RO) – Forces water through a semi-permeable membrane, removing dissolved salts, heavy metals, bacteria, and viruses.

4️⃣ UV Sterilization / Ozone Treatment – Destroys remaining microorganisms, ensuring microbiological safety.

5️⃣ Post-Polishing Filter (Optional) – Provides final filtration to produce crystal-clear, pure water ready for bottling.

Main Advantages

1️⃣ High Water Purity

Effectively removes impurities, bacteria, and harmful substances for safe and clean drinking water.

2️⃣Advanced Filtration Technology

Multi-stage filtration ensures stable and reliable water quality.

3️⃣ Energy-Saving Design

Optimized components minimize energy and water consumption.

4️⃣Durable & Low Maintenance

Built with high-quality materials for long service life

5️⃣Flexible Application

Suitable for beverage, food, and bottled water industries.

6️⃣Intelligent Control System

Automated monitoring for easy operation and fault detection.

Bottle Blowing Machine

High-Speed, Energy-Efficient Bottle Blowing Solutions

NewPeak’s fully automatic bottle blowing machine delivers high-speed performance and precise bottle forming for various plastic packaging applications. Designed for efficiency and durability, it reduces production costs while ensuring consistent quality and easy operation — making it ideal for beverage and bottled water production lines.

Working Principle

The machine adopts a fully automated stretch-blow molding process:

Preform Feeding – An automatic feeding system transports the preforms to the heating zone.

Preform Heating – Infrared heating lamps evenly heat the preforms to the ideal temperature.

Stretch Blow Molding – The preforms are stretched longitudinally and blow-molded laterally under high-pressure air, resulting in high molding precision and uniform wall thickness.

Cooling and Bottle Unloading – After the mold cools and solidifies, the bottles are automatically demolded and output, ready for direct filling.

Advantages

High Efficiency & Consistency

Fast production speed with uniform bottle size, shape, and thickness.Energy Saving

Optimized infrared heating and air circulation system reduce energy consumption.Flexible Production

Quick mold change system supports different bottle shapes and volumes (0.2–2L).Durable & Low Maintenance

High-quality components ensure long service life and minimal downtime.Intelligent Control

PLC + touch screen interface for easy operation, temperature monitoring, and fault diagnosis.

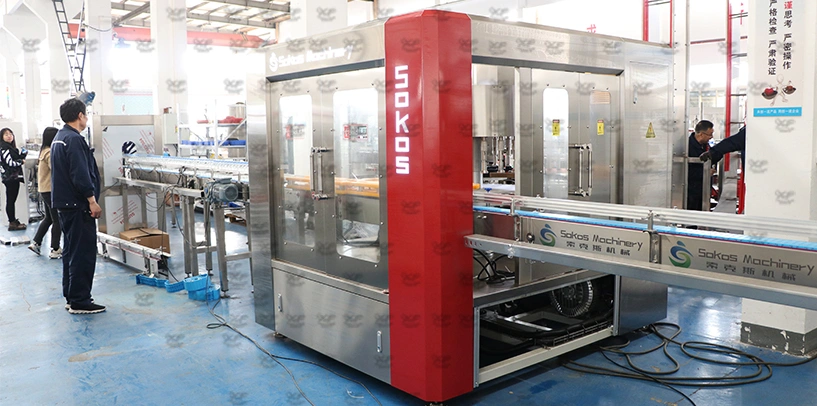

Water Filling Machine

Newpeak water filling machine is made of high-quality 304 stainless steel, ensuring durability, corrosion resistance, and hygienic operation for safe water production. Designed for high efficiency, it provides fast and precise filling to maximize output while minimizing downtime. The energy-saving design reduces power and water consumption, lowering operational costs. Equipped with an intelligent control system, it allows easy operation, real-time monitoring, and automated adjustments. Flexible and reliable, the machine adapts to various bottle types and production lines, providing stable performance for continuous operation.

Product Introduction

Our water filling machine is designed for efficient, precise, and hygienic bottling of water, suitable for industries such as bottled water, beverages, and liquid food production. Constructed with high-quality 304 stainless steel, it ensures durability, corrosion resistance, and safe contact with water.

Working Principle

Bottle Rinsing – Empty bottles are first cleaned with purified water to remove dust and contaminants.

Water Filling – Cleaned bottles are accurately filled to the required volume using gravity or vacuum filling technology, ensuring minimal spillage and high precision.

Capping/Sealing – Filled bottles are automatically capped or sealed, providing a tight, leak-proof finish.

Control & Monitoring – The intelligent control system manages all stages, allowing real-time monitoring, automatic adjustments, and fault detection to ensure stable and reliable operation.

Labeling Machine

Hot Melt Glue Labeling Solutions for Bottles & Containers

NewPeak hot melt glue labeling machines deliver fast, precise, and reliable labeling for a wide range of bottles and containers.

Equipped with advanced hot melt adhesive technology, the system ensures strong and durable labels without damaging the packaging. Its intelligent control system enables automated adjustments, real-time monitoring, and easy operation, making it ideal for modern beverage, food, and liquid product lines.

Working Principle

1️⃣ Bottle Feeding

Containers are automatically conveyed to the labeling station in a stable and consistent manner.

2️⃣ Glue Application

The machine heats and melts adhesive, then applies a controlled amount to the label or container surface.

3️⃣ Label Placement

Labels are accurately positioned and pressed onto the bottle or container, forming a secure bond.

4️⃣ Pressing & Finishing

Rollers or brushes ensure smooth application and adhesion, removing air bubbles and wrinkles.

5️⃣ Control & Monitoring

The intelligent system monitors speed, label position, and adhesive flow, allowing automatic adjustments for consistent performance.

Advantages

High Precision & Efficiency

Fast labeling with accurate alignment and minimal waste.Strong & Durable Adhesion

Hot melt adhesive provides reliable bonding that resists peeling.Energy Saving & Cost Efficient

Optimized heating and control systems reduce power consumption.Intelligent Operation

Automated controls simplify operation and reduce manual intervention.Flexible Application

Suitable for various bottle shapes, sizes, and materials.

Packing Machine

Bottle Water Shrink Wrapping Solutions

NewPeak bottle water shrink wrapping machines provide fast, efficient, and reliable packaging for bottled water production lines.

Using advanced heat-shrink technology, the system tightly wraps multiple bottles in film, ensuring stability, protection, and neat appearance during storage and transport. Intelligent controls allow precise adjustments of speed and temperature, maximizing output while minimizing waste.

Working Principle

1️⃣ Bottle Feeding

Bottles are automatically aligned and conveyed to the wrapping station in stable rows.

2️⃣ Film Application

Heat-sensitive shrink film is fed around the bottles, fully covering them.

3️⃣ Sealing

The machine seals the film edges to ensure bottles are securely wrapped.

4️⃣ Heat Shrinking

Heated shrink tunnels or chambers shrink the film tightly around the bottles, forming neat, uniform packages.

5️⃣ Control & Monitoring

Intelligent systems regulate conveyor speed, temperature, and film tension for consistent quality and minimal waste.

Key Advantages

High-Efficiency Filling: Multi-head filling system with capacity up to several thousand bottles per hour.

Automatic Capping: Automatic cap feeding and capping, reducing manual labor.

Sanitary Design: Made of 304 stainless steel, easy to clean, compliant with food safety standards.

Flexible Compatibility: Supports various bottle types and sizes, adaptable production line configuration.

Energy-Saving: Optimized design for low energy consumption and stable operation.

Request a Quote

Please fill out the following information. We will contact you within one business day.